Tankless water heaters offer a convenient and efficient way to provide hot water on demand. However, ensuring that these units are properly vented is crucial for their safe and efficient operation. Venting not only facilitates the expulsion of harmful gases but also affects the performance and longevity of the heater. This article will explore the essential aspects of venting tankless water heaters, including understanding the requirements, troubleshooting common issues, recognizing the differences between electric and gas models, optimizing performance, and adhering to safety measures and compliance.

Key Takeaways

- Proper venting is essential for the safe operation of tankless water heaters, preventing carbon monoxide buildup and ensuring efficient performance.

- Regular inspection and maintenance of the venting system are necessary to avoid obstructions and blockages that can impair functionality.

- Gas tankless water heaters require specific venting materials and configurations, whereas electric models focus on space and electrical considerations.

- Optimizing venting involves managing condensation in high-efficiency models and adhering to manufacturer guidelines for vent length and bends.

- Safety and compliance are paramount, with strict adherence to local codes and regulations, and avoiding unsafe materials like PVC for venting.

Understanding Venting Requirements for Tankless Water Heaters

Importance of Proper Venting

Proper venting is crucial for the safe and efficient operation of tankless water heaters. Ensuring that hot exhaust gases are safely expelled from the home prevents the risk of fire and the buildup of toxic gases, such as carbon monoxide, which are hazardous to occupants' health. The efficiency and performance of the water heater are also dependent on correct venting, which can extend the unit's lifespan.

Types of venting for tankless water heaters vary, but they all serve the essential function of maintaining proper clearances from windows, doors, and other air intakes to prevent safety hazards. Power venting systems, which use an electric fan to force exhaust gases through the vent pipe, offer flexible installation options but require electrical power and specific clearances.

It is imperative to regularly inspect the venting system for obstructions or damage to ensure it is functioning correctly. An intact and clear vent is vital for the continuous and safe operation of the water heater.

When installing a tankless water heater, always adhere to the manufacturer's guidelines to avoid improper venting, which can lead to the unit shutting off to prevent carbon monoxide buildup or due to insufficient air flow.

Venting System Inspection and Maintenance

Regular inspection and maintenance of your tankless water heater's venting system are essential for ensuring safe and efficient operation. Inspect your tankless water heater exhaust system at least once a year to detect any signs of damage, such as cracks or obstructions, which could compromise the unit's performance or safety.

When examining the venting system, it's crucial to check that all joints are sealed properly and that there are no blockages impeding the flow of exhaust gases. A clear and intact vent is vital for the proper operation of your tankless water heater. Be particularly vigilant for signs of insect infestations, as nests can cause significant blockages.

In certain situations, vent pipe insulation is required to maintain exhaust gas temperatures and prevent condensation. This is especially important in colder climates where the risk of condensation is higher.

Additionally, ensure that the venting system adheres to local codes and the manufacturer's guidelines. This includes maintaining the necessary clearances from windows, doors, and other vents to prevent the dangerous re-entry of exhaust gases into the living space.

- Inspect for damage and blockages

- Verify all joints are sealed

- Check for insect infestations

- Ensure compliance with local codes and manufacturer's guidelines

- Consider vent pipe insulation where necessary

Manufacturer's Guidelines for Vent Installation

When installing vents for tankless water heaters, it is crucial to follow the manufacturer's guidelines closely. These guidelines are designed to ensure that the tankless water heater venting requirements are met, which is essential for the safe and efficient operation of the unit. Adherence to these instructions is also necessary to maintain the validity of the warranty.

Proper vent installation is not just about following the rules; it's about safeguarding the longevity and performance of your tankless water heater.

Manufacturers provide detailed specifications on vent length, diameter, and the number of allowable bends to optimize exhaust flow. Additionally, considerations such as condensate management and vent pipe insulation are outlined to address the unique needs of high-efficiency models. Here are some general points to keep in mind:

- Maintain proper clearances from windows, doors, and other air intakes.

- Ensure vent pipes are insulated where required to maintain exhaust gas temperatures and prevent condensation.

- Power vent systems need electrical power for the fan and must adhere to specific clearance guidelines.

Always consult a qualified professional if you are unsure about any aspect of the vent installation process.

Troubleshooting Common Venting Issues

Dealing with Obstructions and Blockages

Ensuring that your tankless water heater functions efficiently involves regular checks for vent obstructions and blockages. Over time, debris, nests, or even snow can accumulate, restricting airflow and potentially causing your heater to malfunction. To prevent this, it's essential to inspect the venting system periodically.

- Clear the venting system of any debris or blockages

- Verify that the vent pipe is correctly installed

- Maintain the required clearances from windows, doors, and other structures

Clearances are crucial for safety and to prevent exhaust gases from re-entering the building. If you encounter any issues during inspection, it's advisable to consult a professional. Remember, a well-maintained venting system not only ensures optimal performance but also safeguards against potential hazards.

Flushing the system annually is a proactive step that can help in maintaining the integrity of your tankless water heater. This process removes sediment and allows for a check-up of the unit's components.

Ensuring Correct Temperature and Pressure Settings

To maintain optimal performance and safety, it's essential to ensure that your tankless water heater operates within the correct temperature and pressure settings. Incorrect temperature settings can lead to inefficiency and an inability to meet hot water demand. Follow the manufacturer's manual to verify and adjust the temperature as needed.

Proper pressure settings are also crucial for the safe and efficient operation of your tankless water heater. Start by checking the gas supply; for natural gas units, the valve should be parallel to the line when open. For propane units, a pressure gauge should read within the specified range. If the pressure is outside the recommended limits, it may indicate an issue with the gas supply or the need for system maintenance.

Ensuring that both temperature and pressure settings are correct helps prevent potential safety hazards and maintains the integrity of the venting system.

Troubleshooting steps for addressing temperature and pressure issues include:

- Verifying the temperature setting according to the unit's manual

- Inspecting the gas supply and ensuring the valve is correctly positioned

- Checking the pressure gauge for propane units

- Contacting your gas supplier if you're unsure about the pressure readings

Addressing Insect Infestations and Physical Damage

Insect infestations, such as roaches, can pose a significant threat to the venting system of your tankless water heater. Preventative measures are crucial to ensure these pests do not compromise the integrity of the vents. One effective strategy is to fill water traps to their maximum capacity, which acts as a barrier against vermin. Additionally, installing a grid over the drain with holes small enough to keep out large pests can be beneficial.

Physical damage to vents can occur from external impacts or wear over time. It's essential to regularly inspect the venting system for any signs of damage and address them promptly. Here's a simple checklist for maintaining your venting system free from infestations and damage:

- Inspect vents for any visible signs of insect activity or physical damage.

- Ensure water traps are filled to prevent pest entry.

- Install protective grids on drains as a deterrent.

- Repair or replace damaged vent components immediately.

Remember, a well-maintained venting system not only functions efficiently but also contributes to the safety and longevity of your tankless water heater.

Adhering to these practices will help maintain the ventilation system's effectiveness and prevent costly repairs or replacements due to pest-related damage or physical deterioration.

Installation Differences: Electric vs. Gas Tankless Water Heaters

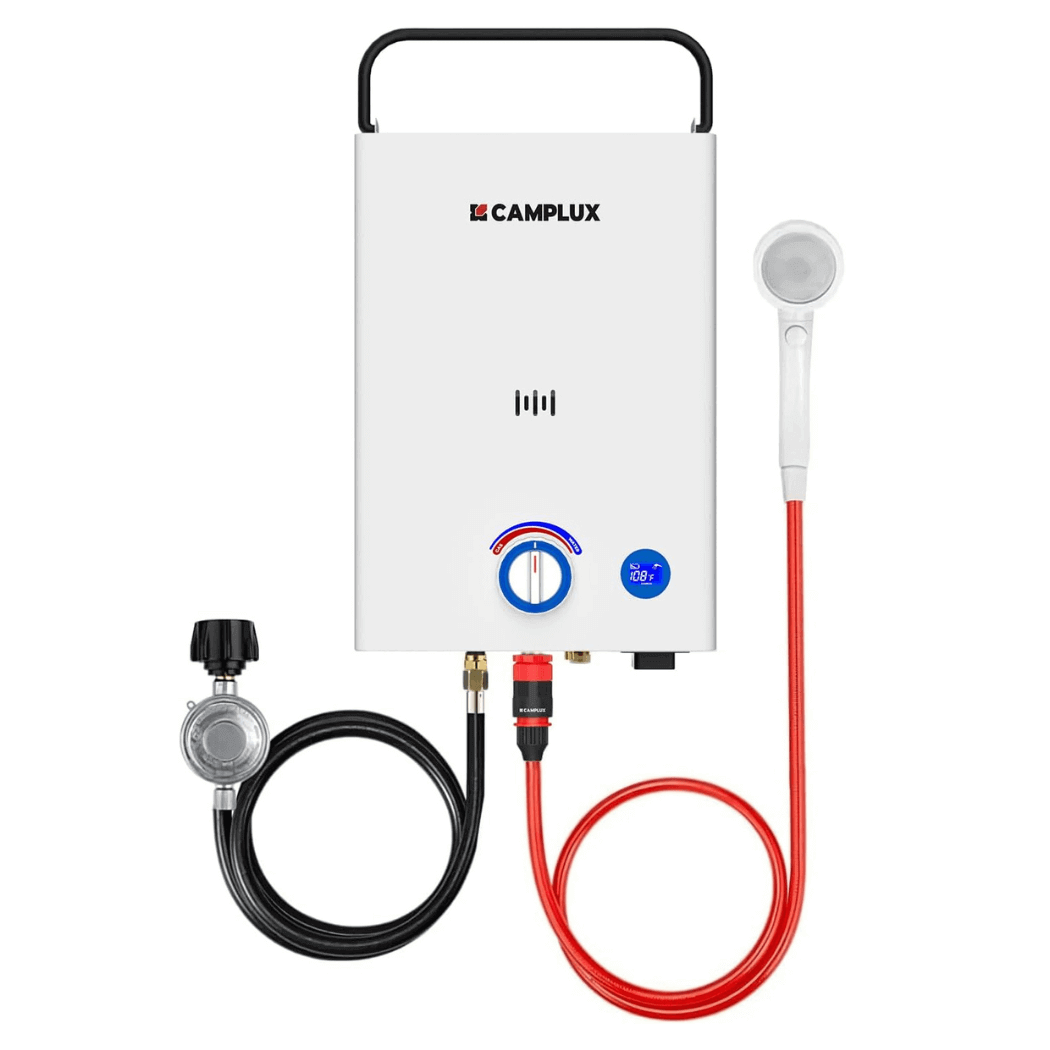

Venting Needs for Gas Tankless Water Heaters

Gas tankless water heaters rely on the combustion of natural gas or propane, necessitating a robust venting system to expel harmful combustion products, such as carbon monoxide, from indoor spaces. Proper venting is crucial to ensure the safety and efficiency of the unit. The venting system must be designed to handle the high temperatures and corrosive nature of the exhaust gases.

Type of Venting Material: Special stainless steel vent pipes are often required for gas tankless water heaters. These materials are chosen for their durability and resistance to the corrosive effects of exhaust gases. The manufacturer's installation guide will provide specific requirements for the venting material.

The venting configuration is another critical aspect. There are two primary configurations:

- Direct Vent Systems, which draw combustion air from outside and vent exhaust gases through a sealed system.

- Atmospheric Venting, which uses the natural buoyancy of hot gases to rise through a vertical vent pipe or chimney.

It is essential to ensure that the venting system is free from obstructions and is installed according to the manufacturer's guidelines to prevent safety hazards such as carbon monoxide buildup.

When installing a gas tankless water heater in a confined space, both a fresh air vent and an exhaust vent are required, typically with a minimum diameter specified by the manufacturer.

Electric Tankless Water Heaters: Ventilation and Space Considerations

While electric tankless water heaters do not require a venting system for exhaust gases, they demand careful attention to electrical and spatial requirements. Proper installation is key to ensuring safe and efficient operation.

Electric units must be provided with adequate amperage, voltage, and circuit breaker specifications. It's essential to maintain a few inches of space on all sides and at least 12-18 inches of clearance on top for heat dissipation and maintenance access.

In tightly sealed or small spaces, additional ventilation may be necessary to prevent moisture buildup and to manage the heat generated by the unit. This is especially critical in closet installations or confined areas.

Space Considerations for Electric Tankless Water Heaters:

- Maintain a minimum of a few inches of clearance on all sides

- Ensure at least 12-18 inches of clearance on top

- Provide additional ventilation in tightly sealed or confined spaces

Adhering to these guidelines not only optimizes the heater's performance but also contributes to the longevity of the device. Always consult the manufacturer's manual for specific installation instructions and clearances to avoid any potential issues.

Choosing the Right Venting Material and Configuration

Selecting the appropriate venting material and configuration for your tankless water heater is crucial for both performance and safety. The type of venting material is determined by the heater's requirements; for instance, gas tankless water heaters typically need special stainless steel vent pipes. These pipes are designed to endure the high temperatures and corrosive nature of exhaust gases, as specified in the manufacturer's installation guide.

When it comes to venting configurations, there are several options:

- Direct Vent Systems use a sealed vent to draw combustion air from outside and expel exhaust gases, ideal for tightly sealed homes.

- Power Vent Systems utilize an electric fan to expel exhaust, offering flexible installation with horizontal or vertical routing.

- Atmospheric Venting relies on the natural rise of hot gases through a vertical vent, requiring a minimum vertical rise and termination above the roofline.

It's essential to maintain proper clearances from windows, doors, and other air intakes to ensure safety and compliance with local codes.

Additionally, vent pipe insulation may be necessary to maintain exhaust gas temperatures and prevent condensation. The specific requirements for insulation and clearances can vary, so it's important to consult local codes and the manufacturer's instructions.

Optimizing Performance with Proper Venting

Maximizing Exhaust Flow: Vent Length and Bends

To ensure the efficient operation of a tankless water heater, attention to vent length and bends is crucial. Manufacturers provide guidelines on the maximum vent length and the allowable number of bends to maintain optimal exhaust flow. Exceeding these specifications can lead to reduced efficiency and potential safety hazards.

Proper venting is not just about meeting minimum requirements; it's about optimizing for performance and safety.

The total length of the vent pipe and the number of elbows or bends directly impact the system's ability to expel exhaust gases effectively. Here are some considerations for maintaining efficient exhaust flow:

- Maintain proper clearances from windows, doors, and other air intakes to prevent exhaust gas re-entry.

- Use the minimum number of bends to reduce resistance and improve flow.

- Ensure that vent pipes are properly insulated in certain situations to maintain exhaust gas temperatures and prevent condensation.

Remember, while power venting offers flexibility in installation, it requires electrical power for the fan and adherence to specific clearance requirements.

Condensation Management in High-Efficiency Models

High-efficiency condensing tankless water heaters are designed to extract more heat from the combustion process, which leads to the formation of condensate. Proper management of this condensate is crucial to prevent damage to the unit and ensure efficient operation. The acidic nature of the condensate requires specific materials and installation practices for the drainage system.

Condensate drainage must be carefully planned to avoid corrosion and leaks. Here are some key considerations:

- Use corrosion-resistant materials for the drain pan and piping.

- Ensure the drain line is properly sloped to facilitate flow.

- Protect against freezing in colder climates by insulating the drain line.

It's essential to follow the manufacturer's guidelines for condensate management to maintain the integrity and performance of your tankless water heater.

Efficiency and performance are intertwined with proper venting and condensate management. Regular maintenance, including descaling the heat exchanger and inspecting the venting system, can extend the life of the appliance and reduce energy costs.

Power Venting: Flexibility and Electrical Requirements

Power venting offers a versatile solution for tankless water heater installations, especially when traditional vertical venting is not feasible. Power vent systems use an electric fan or blower to expel exhaust gases, which allows for horizontal venting and termination on a side wall. This flexibility can be a significant advantage in buildings where vertical runs are impractical.

However, these systems come with their own set of requirements:

- Adequate electrical power to operate the fan or blower.

- Maintenance of specific clearances from windows, doors, and air intakes to prevent exhaust gas re-entry.

- Adherence to local codes and manufacturer's guidelines for vent pipe insulation to maintain exhaust gas temperatures and prevent condensation.

It is crucial to ensure that the electrical requirements for power venting, such as amperage, voltage, and circuit breaker specifications, are met to maintain safety and efficiency.

Selecting the right vent material and configuration is also essential to optimize performance and comply with safety standards. Manufacturers provide guidelines on maximum vent length and the allowable number of bends to ensure proper exhaust flow, which must be followed meticulously to avoid compromising the heater's efficiency and safety.

Safety Measures and Compliance

Avoiding the Use of Unsafe Venting Materials like PVC

When installing a tankless water heater, it's crucial to avoid the use of PVC vent pipes due to their inadequate heat tolerance and potential safety hazards. PVC, or Polyvinyl Chloride, is a material that can soften, warp, or even melt when exposed to the high temperatures of exhaust gases, leading to structural failure and the risk of fire or carbon monoxide poisoning.

The use of PVC as a venting material is not only a safety concern but also a common cause for code violations. Non-compliance with building codes can result in fines, insurance issues, and complications during property sales.

For safe venting, consider alternative materials that are designed to withstand the temperatures and conditions associated with gas water heaters. Here's a list of safer venting materials:

- Stainless steel

- AL29-4C special stainless steel

- Category III and IV venting systems

Always consult the manufacturer's guidelines and local building codes to ensure that the venting system you choose is appropriate and safe for your specific tankless water heater model.

Maintaining Clearances from Intakes and Openings

Ensuring that your tankless water heater has the proper clearances from intakes and openings is crucial for both safety and performance. Clearances are designed to prevent fire hazards and facilitate proper ventilation, which is essential for the efficient operation of the water heater. The intake pipe should be positioned in an area with access to fresh outdoor air, such as an exterior wall, while the exhaust pipe should expel the combustion gases safely away from the building.

Maintaining specific clearances from windows, doors, air intakes, and other structures is vital to prevent exhaust gas re-entry into the building.

Additionally, it's important to adhere to local building codes and the manufacturer's specifications when determining these clearances. For instance, there should be a minimum clearance above the water heater to allow for venting connections and servicing, typically recommended to be 12 to 18 inches. In some cases, vent pipe insulation may be required to maintain exhaust gas temperatures and prevent condensation issues.

Remember to always provide sufficient clearance to allow for proper heat dissipation and to facilitate inspections and maintenance. This will ensure that your tankless water heater operates safely and at its best capacity.

Adhering to Local Codes and Regulations

Ensuring that your tankless water heater's venting system is in compliance with local building codes and the manufacturer's installation instructions is not just a good practice—it's a legal requirement. Local codes can vary significantly, and non-compliance can lead to safety risks, fines, and issues with insurance coverage. It's crucial to consult a qualified professional if there's any doubt about venting compliance.

When installing or inspecting your venting system, remember to:

- Maintain the required clearances from windows, doors, and other structures as specified by local codes and manufacturer's guidelines.

- Adhere to the specified length and number of bends for vent pipes to ensure efficient operation.

- Use the correct materials and methods for venting, as improper materials like PVC may violate codes.

In certain situations, insulation of vent pipes is necessary to maintain exhaust gas temperatures and prevent condensation. The requirements for this, including the type of insulation and clearance, are dictated by local regulations and the manufacturer's specifications.

Always keep in mind that the vent clearances for water heaters are there to prevent exhaust gas from re-entering the building and to guarantee the safety of the occupants. Adhering to these guidelines is essential for the safe and efficient operation of your tankless water heater.

Conclusion

Proper venting is essential for the safe and efficient operation of tankless water heaters. Throughout this article, we've explored the critical aspects of venting systems, from the importance of clear and sealed vents to the specific requirements for gas and electric models. Remember to always follow the manufacturer's guidelines for installation and maintenance, and to be vigilant for signs of blockage or damage. Whether you're dealing with condensation management in high-efficiency models or ensuring adequate space for heat dissipation, taking the time to properly vent your tankless water heater will ensure it operates at its best, providing you with endless hot water while keeping your home safe.

Frequently Asked Questions

Why is proper venting crucial for tankless water heaters?

Proper venting is essential for the safe operation of tankless water heaters. It ensures the removal of combustion gases, including carbon monoxide, and prevents blockages that could cause the unit to shut off or create hazardous conditions.

How often should I inspect and maintain the venting system of my tankless water heater?

The venting system should be inspected regularly for any obstructions, damage, or improper installation. Maintenance frequency can vary, but it's generally recommended to inspect the system annually or as specified by the manufacturer's guidelines.

What are the differences in venting requirements between electric and gas tankless water heaters?

Gas tankless water heaters require venting systems to expel combustion gases, often using special materials like stainless steel. Electric tankless water heaters do not combust fuel and therefore do not require a venting system for gases, but may need space for heat dissipation.

What should I do if I find an obstruction or blockage in my water heater's vent?

If you discover an obstruction, such as an insect nest or debris, it should be removed immediately. Ensure the vent is intact and clear to maintain proper operation. If the blockage is significant or if there's physical damage, professional service may be required.

Can I use PVC pipes for venting my gas tankless water heater?

No, PVC pipes are not safe for venting gas tankless water heaters due to the high temperatures and corrosive nature of the exhaust gases. Manufacturers typically require specific types of venting materials, like stainless steel, that can withstand these conditions.

What is power venting and when is it necessary?

Power venting uses an electric fan or blower to force exhaust gases through the vent pipe, allowing for more flexible installation options, such as horizontal runs. It's necessary when the venting system cannot rely on natural draft and requires electrical power to operate.